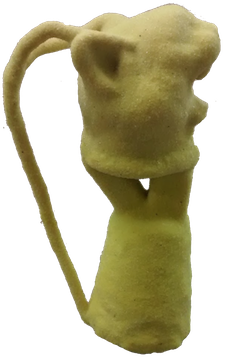

Original Clay Model

Once the artist has finished the clay model, the process has just begun!

The rest of the steps are most often done at a foundry. I prefer to do them myself to keep it one artist's artwork.

The rest of the steps are most often done at a foundry. I prefer to do them myself to keep it one artist's artwork.

Silicon Mold

A silicon mold is made surrounding the clay to capture the finest of details.

This mold is reused over and over to create all the wax castings.

This mold is reused over and over to create all the wax castings.

Wax Casting

A hollow wax casting is made from the mold.

Each wax will be destroyed in the process of making a bronze casting.

Each wax will be destroyed in the process of making a bronze casting.

Sprued Wax

The wax has a pouring cup and various wax channels (called sprues and gates) and vents attached to it.

These provide a path for molten metal to flow and to allow air to escape.

These provide a path for molten metal to flow and to allow air to escape.

Ceramic Shell

The wax assembly is dipped alternately in liquid ceramic and sand repeatedly to build proper thickness.

This ceramic 'shell' will contain the molten metal as it pours into the empty space where the wax replica was.

This ceramic 'shell' will contain the molten metal as it pours into the empty space where the wax replica was.

Burned Out Shell

After drying, the ceramic shell is placed into a kiln around 1600-1800°F.

This melts the wax out of the shell leaving a cavity for the molten metal to flow into. This also strengthens the ceramic shell, which will soon channel and contain molten bronze at 2100°F.

This melts the wax out of the shell leaving a cavity for the molten metal to flow into. This also strengthens the ceramic shell, which will soon channel and contain molten bronze at 2100°F.

Molten Metal

Bronze ingots in a crucible are melted in a furnace to around 2100°F.

The bronze is then poured into the ceramic shell.

The cherry red color is after the leftover metal has cooled quite a bit.

The bronze is then poured into the ceramic shell.

The cherry red color is after the leftover metal has cooled quite a bit.

Fresh Casting

After the metal casting cools, most of the ceramic shell is easy to remove with a hammer and chisel.

Ready for Chasing

Next the metal pouring cup, sprues, gates and vents, as well as most of the ceramic shell are removed.

Now the casting is ready to be cleaned up further in a process known as chasing.

Now the casting is ready to be cleaned up further in a process known as chasing.

After Chasing, Ready for Patina

Chasing involves grinding, sandblasting, and sometimes welding to restore the casting to a perfect finish.

The casting now looks just like a hollow version of the clay model, and is ready for its patina.

The casting now looks just like a hollow version of the clay model, and is ready for its patina.

Final Sculpture

A patina is applied to the sculpture with various weak acids and/or oxides to give it a desired coloration.

Without a patina, bronze will naturally tarnish (or oxidize) until it turns black or green.

The patina allows the artist to choose the permanent colors, and then it is laquered and waxed to protect the patina.

Without a patina, bronze will naturally tarnish (or oxidize) until it turns black or green.

The patina allows the artist to choose the permanent colors, and then it is laquered and waxed to protect the patina.